Home > Research > Research Results > Research Results 2018 > Combined heat and power (CHP) woody biomass projects are highly economical

Update:July 17, 2018

Main content starts here.

Combined heat and power (CHP) woody biomass projects are highly economical

| Article title |

Conditions for Establishing a Combined Heat and Power Station by Using Unutilized Wood Biomass |

|---|---|

| Author (affiliation) |

Hirofumi Kuboyama(a), Hirotaka Komata(b), Takashi Yanagida(c) (a) Department of Forest Policy and Economics, FFPRI, Tsukuba, Ibaraki, Japan. (c) Department of Wood Properties and Processing, FFPRI, Tsukuba, Ibaraki, Japan. |

| Publication Journal |

Journal of the Japanese Forest Society, 99(6):226-232, December 2017, DOI: 10.4005/jjfs.99.226( External link ) |

| Content introduction |

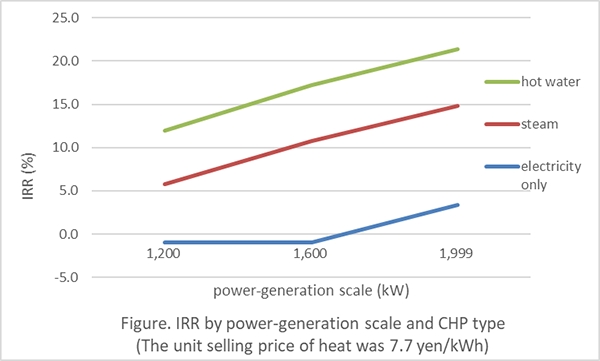

The recently opened biomass power-generation facilities that burn unutilized wood biomass in Japan often have low power-generation efficiency of ~25% and high equipment and fuel costs. These factors limit the economic efficincy of such plants. However, economic efficiency can be improved even in small- and medium-scale facilities with the adoption of a combined heat and power (CHP) system that can utilize heat and electricity generated from burning wood biomass. To assess the feasibility of this approach, a CHP evaluation tool has been developed (available to the public (in Japanese) for free: https: //www.ffpri.go.jp/database/hatsuden/hatsuden.html). A detached power plant, 1) electricity only and two types of CHPs, 2) steam, and 3) hot water with four power-generation scales (1,200; 1,600; 1,999; and 5,700 kW), were examined by the internal rate of return (IRR). The unit selling price of heat was set to either 7.7 or 5.2 yen/kWh, assuming the price of heavy oil as a reference. The assessment clarifies the following points: a) in the case of small- to medium-sized systems, economic efficiency is increased by CHP; b) in the case of 1,200 kW, because of the low power-generation efficiency, economic efficiency could not be ensured even with CHP if the unit selling price of heat is low; c) in the CHP project, hot water is the most economical heat demand, as its effect on the electricity generation is less than steam; and d) to actually undertake the CHP project, the integration of heat demand is required in the facility’s service area. This integration can involve multiple energy consumers, such as large hospitals and hotels. If wood biomass power is generated while selling heat to such entities, those plants could realize sustainable business with significantly contributing to regional development.

Figure: If power generation is between 1,200 and 1,999 kW, the internal rate of return (IRR) is higher in the CHP project that uses the heat utilization methods than when only electricity is generated. It is indicating that the economic efficiency is improved by the CHP project (the negative value of the internal rate of return is assumed to be −1% because it cannot be calculated accurately). However, the integration of heat demand becomes an issue when the heat utilization of the CHP project reaches 4,333–6,296 kWth. |

Copyright © Forest Research and Management Organization. All rights reserved.