Home > Research > Research Results > Research Results 2018 > Investigation of the Joint Strength of Wood-Based Panel Materials Used in Medium-Rise Large-Scale Wooden Buildings

Update:October 15, 2018

Main content starts here.

Investigation of the Joint Strength of Wood-Based Panel Materials Used in Medium-Rise Large-Scale Wooden Buildings

| Article title |

Single shear properties and deformation behavior of nailed joints using various structural panel materials |

|---|---|

| Author (affiliation) |

Keita Ogawa (a), Masaki Harada (a), Tatsuya Shibusawa (a), Kohta Miyamoto (a) (a) Department of Wood Engineering, FFPRI, Tsukuba, Ibaraki, Japan. |

| Publication Journal |

Mokuzai Gakkaishi, 64(4):139-148, July 2018, DOI:10.2488/jwrs.64.139( External link ) |

| Content introduction |

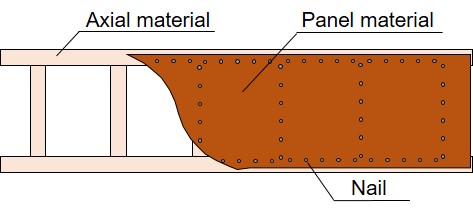

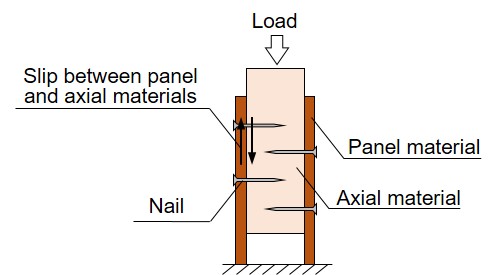

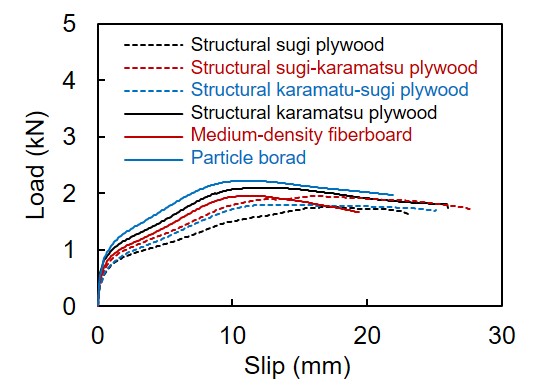

In recent years, the development of materials with superior strength performance has been a priority because of increased expectations of builders of medium-rise large-scale wooden buildings. During the development of assembling components such as box beams, which combine panel and axial materials (flanges, stiffeners, etc.), that may be used in such construction, it is necessary to determine shear properties(Note1) of the joints between panel and axial materials. Such joints are generally made using nails. Therefore, we sought to determine the shear property of nailed joints by simulating their use in assembling components of medium-rise large-scale wooden buildings. The shear properties of test pieces in which a panel material (four types of structural plywood, a type of medium-density fiberboard, or a type of particle board) and an axial material (cedar or larch timbers) were joined by CN75 nails(Note2) were investigated to determine the relationship between strength performance and the panel material. For example, joints using larch plywood or particle board exhibited higher strength than those using other panel materials. In addition, joint deformation upon force application was assessed and showed that CN75 nails are unlikely to cause reduction in the yield strength because of nail withdrawal, which is not the case with CN50 nails that are frequently used in general construction, such as houses. These findings will contribute to the development of components with superior strength performance, which will lead to the promotion of construction of wooden medium-rise and large-scale buildings.

(Note1) Load-bearing performance against a load that causes slippage between two joined materials. (Note2) One of the “common nails (thick iron-wire nails)” standardized by Japanese Industrial Standards (diameter and shank length of 3.76 and 76.2 mm, respectively). CN75 nails are thicker and longer than CN50 nails (diameter and shank length of 2.87 and 50.8 mm, respectively) that are used for joining the panel material to axial material during general construction, such as houses.

Fig.2. An experiment investigating shear properties of the nailed joints

Fig.3. An example of the relationship between load and slippage (cedar was used as the axial material) |

Copyright © Forest Research and Management Organization. All rights reserved.