Home > Research > Research Results > Research Results 2019 > Development of two-hour fireproof performance for all-wooden materials not covered by plasterboard

Update:March 25, 2019

Main content starts here.

Development of two-hour fireproof performance for all-wooden materials not covered by plasterboard

| Article title |

Two-hour fireproof performance of cross-laminated timber covered with fire-retardant impregnated wood |

|---|---|

| Author (affiliation) |

Toshiro Harada (a), Daisuke Kamikawa (b), Atsushi Miyatake (c), Kenta Shindo (c), Nobuaki Hattori (d), Keisuke Ando (d), Masayuki Miyabayashi (e) (a) Research Director, FFPRI, Tsukuba, Ibaraki, Japan. (b) Department of Wood Improvement, FFPRI, Tsukuba, Ibaraki, Japan. (c) Department of Wood-based Materials, FFPRI, Tsukuba, Ibaraki, Japan. (d) Tokyo University of Agriculture and Technology, Fuchu, Tokyo, Japan. (e) T. E. Consulting Inc., Tokyo, Japan. |

| Publication Journal |

Mokuzai Gakkaishi, 65(1):46-53, January 2019 DOI:10.2488/jwrs.65.46( External link ) |

| Content introduction |

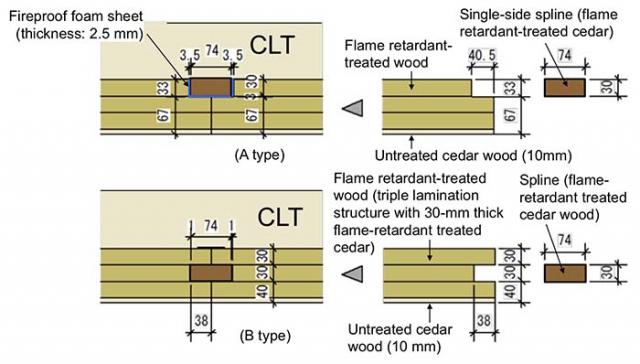

Cross-laminated timber (CLT) is a promising wood-based structural component with the potential to become a cost-effective building solution for institutional, residential, and commercial buildings as well as industrial facilities. CLT is a thick panel-shaped material, in which lamina thickness should be approximately 30 mm. In Europe and North America, CLT is used as a construction material for mid-to-high rise structures. In Japan, the Building Standards Law requires that CLT developed for mid-to-high rise structures be fire resistant. The application of two-hour fireproof performance is also important for the walls and floors of ultra-high rise buildings. For sustainable wood building materials, our group has contributed to the development of two-hour fireproof CLT materials covered with inorganic materials such as plasterboard. Recently, we offered a press release to announce the approval of two-hour fireproof structures for certification by The Ministry of Land, Infrastructure, Transport and Tourism. However, a two-hour fireproof CLT structure constructed “only” of wood materials is yet to be developed. Using technology developed from one-hour fireproof glued-laminated timber pillars and beams covered with wooden materials filled with a fire-retardant agent, we developed a specification for the application of two-hour fireproof performance using wooden panels with treated cedar wood. These panels comprised 90-mm thick of flame retardant-treated cedar wood and 10-mm thick untreated cedar wood, attached to the CLT with screws. We also conducted a two-hour fireproof test for floor construction from the undersurface. Unlike cases involving pillars and beams, when covering floors and walls with flame retardant-treated wood panels, a seam (joint) will always occur and this may be associated with a weak area. This problem can be resolved using a flame retardant-treated spline joint (Figure1). In this manner, two-hour fireproof CLT structures can be developed without using plasterboard.

Figure1. Two-hour fireproof CLT specification(mm units).

Left:The CLT surface was not carbonized when removing lagging materials. Right:Approximately 30-mm thickness of the fireproof lagging material panels (total thickness was 100mm) was in an uncarbonized state. |

Copyright © Forest Research and Management Organization. All rights reserved.