Home > Research > Research Results > Research Results 2019 > A new era of processing technology that can lead to food production from wood

Update:June 12, 2019

Main content starts here.

A new era of processing technology that can lead to food production from wood

| Article title |

Simultaneous enzymatic saccharification and comminution for the valorization of lignocellulosic biomass toward natural products |

|---|---|

| Author (affiliation) |

Ronald R.Navarro (a), Yuichiro Otsuka (a), Masanobu Nojiri (a), Shigehiro Ishizuka (b), Masaya Nakamura (a), Kazuhiro Shikinaka (c), Kenji Matsuo (d), Kei Sasaki (e), Ken Sasaki (e), Kazuhide Kimbara (f), Yutaka Nakashimada (d), Junichi Kato (d) (a) Department of Forest Resource Chemistry, FFPRI, Tsukuba, Ibaraki, Japan. (b) Department of Forest Soils, FFPRI, Tsukuba, Ibaraki, Japan. (c) National Institute of Advanced Industrial Science and Technology, Sendai, Miyagi, Japan. (d) Hiroshima University, Higashihiroshima, Hiroshima, Japan. (e) Hiroshima Kokusai Gakuin University, Hiroshima, Japan. (f) Shizuoka University, Hamamatsu, Shizuoka, Japan. |

| Publication Journal | BMC Biotechnology, 18:79, Springer Nature, December 2018 DOI:10.1186/s12896-018-0487-1( External link ) |

| Content introduction |

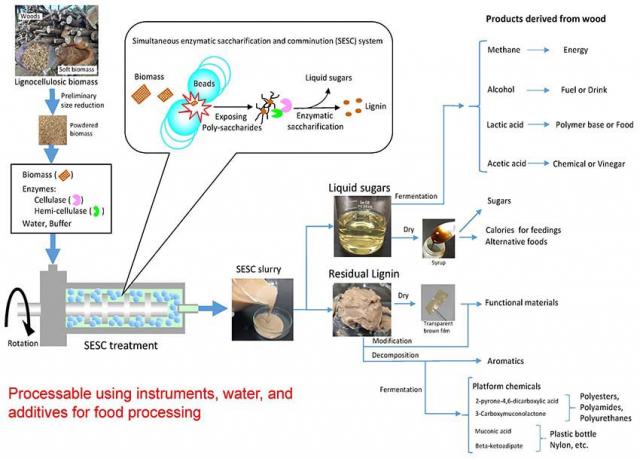

The primary components of wood are cellulose, hemicellulose, and lignin as well as a trace amount of extracts. Because these components form rigid cell walls, chemical and hydrothermal treatments are required to separate and use each of these components. However, such chemical and hydrothermal treatments pose a large environmental burden and produce toxic materials as byproducts. Consequently, the use of wood components is limited. The Forestry and Forest Products Research Institute has been developing a novel processing technology, termed the simultaneous enzymatic saccharification and comminution (SESC) system, that does not require chemical or hydrothermal treatments. In this system, fibrous cellulose and hemicellulose components are exposed from cell walls in water by milling wood under 1/1000 mm using beads with a density six-fold greater than that of water. Simultaneously, the released cellulose and hemicellulose are enzymatically degraded to saccharides, such as glucose and xylose, and solubilized. Lignin, another primary component of wood, is recovered as a residue. As shown in the figure, the saccharides (e.g., glucose and xylose) produced by this system can be used as saccharides or to produce methane gas, alcohol, lactic acid, or acetic acid via bacterial fermentation. Residual lignin can be used as a new functional material and for the production of industrial raw materials by chemical decomposition and bacterial fermentation. In this study, the optimum conditions for SESC were determined. We also demonstrated that SESC could be scaled up without any issue and that the produced saccharide-containing solution could be directly used for fermentation. It was also confirmed that the SESC treatment and alcohol fermentation could be performed using water and additives for food processing. Taken together, these findings indicate the potential applications of wood as a food source, which was previously considered impossible. Lastly, using this technology, preliminary production of wood-scented alcohol resulted in the world’s first “wood wine”.

Figure: Novel utilization of wood by simultaneous enzymatic saccharification and comminution (SESC) |

Copyright © Forest Research and Management Organization. All rights reserved.