Home > Research > Research Results > Research Results 2019 > The detailed resistance behavior of the veneers in plywood under embedment loading by a nail

Update:June 28, 2019

Main content starts here.

The detailed resistance behavior of the veneers in plywood under embedment loading by a nail

| Article title |

Method for measuring the resistances produced on parallel and perpendicular veneers in plywood under nail embedment loading |

|---|---|

| Author (affiliation) |

Keita Ogawa (a), Masaki Harada (a), Tatsuya Shibusawa (b), Kohta Miyamoto (b) (a) Department of Wood Engineering, FFPRI, Tsukuba, Ibaraki, Japan. (b) Department of Wood-Based Materials, FFPRI, Tsukuba, Ibaraki, Japan. |

| Publication Journal |

Journal of Wood Science, 65:1, February 2019 DOI:10.1186/s10086-019-1786-4( External link ) |

| Content introduction |

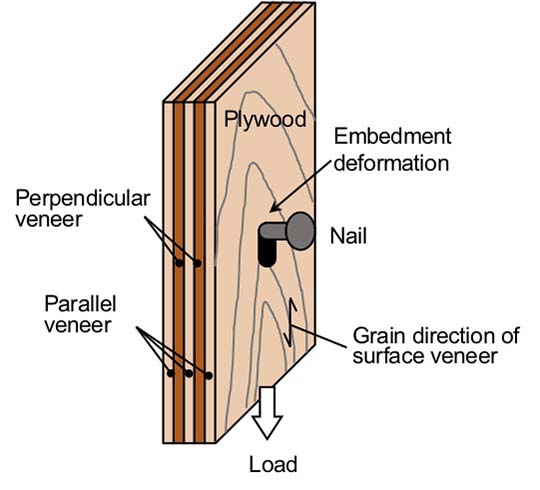

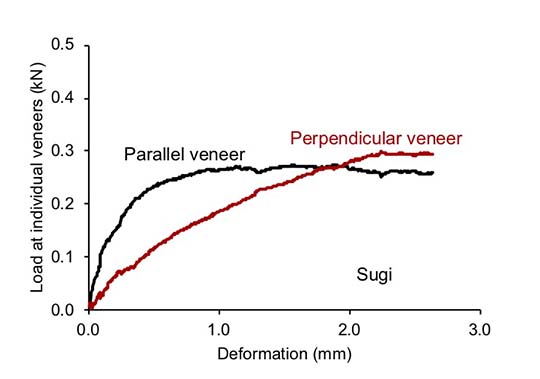

Plywood is a wooden board produced by laminating and gluing veneers (i.e., a sheet-like material obtained by the rotary cutting of logs) such that the grain directions are orthogonal with each other. Plywood, which is frequently used for structural diaphragms, such as the walls and floors of wooden buildings, is often joined with the frame members (e.g., columns and beams) using nails; hence, the performance of the joint considerably influences the strength of the wooden structures. The mechanical performance of wood varies depending on the grain direction, whereas the strength and the deformation performance of the nail joint vary depending on the grain direction of the veneer. This study clarified the mechanical behaviors in the veneers in the parallel and perpendicular grain directions with respect to the loading direction under embedment loading using a nail. A mechanical test was conducted using the plywood specimens, and the mechanical behaviors in the each veneer were separately evaluated using a comparatively simple numerical model. It was revealed that the veneer in the parallel direction exhibited a larger resistance in the range of small deformation when compared with that in the perpendicular direction. The difference in resistance between the two decreased with increasing deformation. This result clarified the basic material characteristics of the plywood used in nail joints. In the future, by utilizing the results, we intend to develop novel wooden materials that exhibit enhanced performance of nail joints and elucidate their strength characteristics.

Figure1. A state in which embedment deformation occurs in the nailed joint of plywood. Here, embedment deformation simultaneously occurs in two types of veneers in the parallel and perpendicular grain directions in plywood. The embedment behavior was simulated using a numerical model.

Figure2. Mechanical behavior of the veneers constituting plywood (structural sugi plywood as the test specimen material). In the small deformation range, the veneer in the parallel grain direction exhibits a higher resistance when compared with that in the perpendicular direction; however, the difference between the resistances of the two types becomes smaller in the large deformation range. |

Copyright © Forest Research and Management Organization. All rights reserved.