Home > Research > Research Results > Research Results 2020 > Creating polymer raw materials from wastewater produced during wood pulp manufacturing

Update:October 9, 2020

Main content starts here.

Creating polymer raw materials from wastewater produced during wood pulp manufacturing

| Article title |

Development of the production of 2-pyrone-4,6-dicarboxylic acid from lignin extracts, which are industrially formed as by-products, as raw materials |

|---|---|

| Author (affiliation) |

Yuzo Suzuki (a), Yuriko Okamura-Abe (b), Masaya Nakamura (a), Yuichiro Otsuka (a), Takuma Araki (a), Hiroyuki Otsuka (b), Ronald R. Navarro (c), Naofumi Kamimura (d), Eiji Masai (d), Yoshihiro Katayama (e) (a) Department of Forest Resource Chemistry, FFPRI, Tsukuba, Ibaraki, Japan. (b) Tokyo University of Agriculture & Technology, Koganei, Tokyo, Japan. (c) Phil-Japan Worldwide Management Services, Inc., Makati, Metro Manila, Philippines. (d) Nagaoka University of Technology, Nagaoka, Niigata, Japan. (e) Nihon University, Fujisawa, Kanagawa, Japan. |

| Publication Journal |

Journal of Bioscience and Bioengineering, 130(1), 71-75, July 2020 DOI:10.1016/j.jbiosc.2020.02.002( External link ) |

| Content introduction |

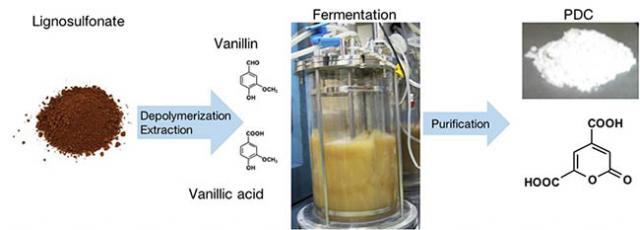

Lignin, which makes up 25-35% of woody biomass, is the most abundant aromatic polymer compound in the biosphere. During the process of manufacturing pulp from woody biomass using sulfurous acid, lignin is converted into lignosulfonate and eluted in effluent. Lignosulfonate is used as a water-reducing agent in concrete and as a dye dispersant. In this study, we are aiming to develop new technologies for reusing materials that are discharged during the pulp manufacturing process. We have found that PDC (2-pyrone-4,6-dicarboxylic acid) can be produced by fermentation from vanillin and vanillic acid that are obtained when lignosulfonate is subjected to alkaline oxidation. PDC is produced by fermentation from them which are products of the decomposition of lignin and can become a useful biodegradable raw material for producing heat-resistant films, flexible polyurethanes, and strong epoxy adhesives, among other things. The results of this study will contribute to the development of technologies for making the maximum use of woody components as versatile resources.

|

Copyright © Forest Research and Management Organization. All rights reserved.