Home > Research > Research Results > Research Results 2020 > Implementing a methodology for feeding wood materials into a hopper increases the efficiency of wood chip production

Update:October 16, 2020

Main content starts here.

Implementing a methodology for feeding wood materials into a hopper increases the efficiency of wood chip production

| Article title |

Effects of dimension and species of wood materials on the energy consumption and cost during comminution by a disc chipper |

|---|---|

| Author (affiliation) |

Kiyohiko Fujimoto(a), Tatsuya Sasaki(b), Yuji Ikami(a), Takahiro Yoshida(a), Tsutomu Takano (c) (a) Department of Wood Properties and Processing, FFPRI, Tsukuba, Ibaraki, Japan. (b) Department of Forest Engineering, FFPRI, Tsukuba, Ibaraki, Japan. (c) Center for Forest Restoration and Radioecology, FFPRI, Tsukuba, Ibaraki, Japan. |

| Publication Journal |

Bulletin of FFPRI, Vol.19-No.2 (No.454)115-119 August 2020 URL:https://www.ffpri.go.jp/pubs/bulletin/454/454toc-en.html |

| Content introduction |

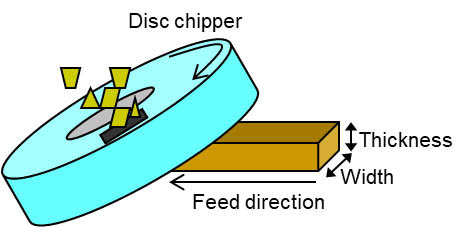

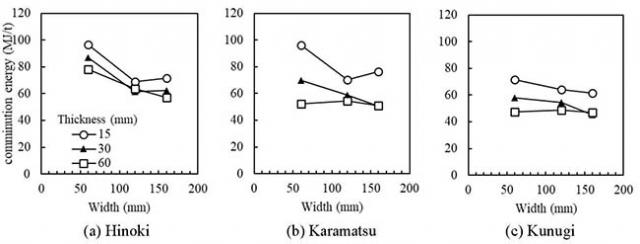

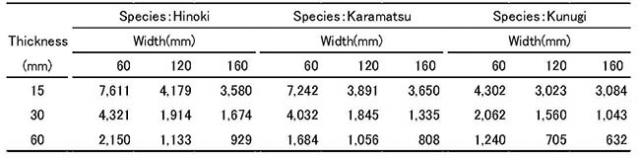

The use of energy from wood biomass is proceeding as one measure for countering global warming. When converting wood biomass from wood waste, etc., into an energy resource, the wood is crushed into chips, and the wood chips are sold at a low price. Therefore, in order to reduce costs during the comminution process, we have been conducting research to make the process more efficient by experimenting with the dimensions, density, and species of wood resources. We prepared wood samples from various tree species having a length of 800mm, but different widths and thicknesses. The energy consumed during the comminution process was measured, and the data obtained therefrom were used to calculate chip production costs. As a result, we could see that both the production energy consumed per 1 ton of chips and production costs decreased with increasing dimensions and density. Given the limitations on performance due to the size of the equipment, as well as limitations on the size of hoppers, we found that feeding materials that were as large and as dense as possible into the hoppers could keep production energy costs down. Based on the results of this research, we found that a company could increase the efficiency of its chip production equipment merely by establishing a methodology for feeding raw wood materials, a task that is very easy to implement at the work site.

Figure 2 Energy used in chip production (MJ/t). Density: Hinoki 498kg/m3, Karamatsu 521kg/m3, Kunugi 812kg/m3.

Table1 Chip production costs (Yen/t). |

Copyright © Forest Research and Management Organization. All rights reserved.